Belt Filter for Continuous

Liquid Filtration

A belt filter ensures the continuous purification of liquids and keeps process conditions stable. CENTRIPURE™ systems from SIEBEC separate solids, oils and sludge reliably and maintain constant temperature when required. The purified liquid flows into a dedicated pure tank to guarantee a fully filtered and process-safe return.

CENTRIPURE™ – Industrial Belt Filter Systems for Water Treatment

A belt filter is an automatic filtration system for the continuous purification of liquids, especially in industrial applications such as cooling and lubricating fluids, process water or galvanic baths. It is part of mechanical solid-liquid separation and operates with unwinding filter fleece (also known as filter belts or roll media), which filters solids out of the liquid. This automatic media feed reflects the principle of a continuous belt filter.

This challenge is solved by a belt filter

Belt filters like CENTRIPURE™ address several challenges in industrial filtration processes. They reliably remove the finest particles and sludge through automatic belt and magnetic filtration. In oil-laden liquids, integrated microfiber elements and skimmers effectively reduce the oil content. The optional temperature control ensures consistent conditions in the process and protects against fluctuations. At the same time, the 100% filtered return prevents unplanned downtime and significantly reduces wear on machines and tools.

Our belt filters at a glance

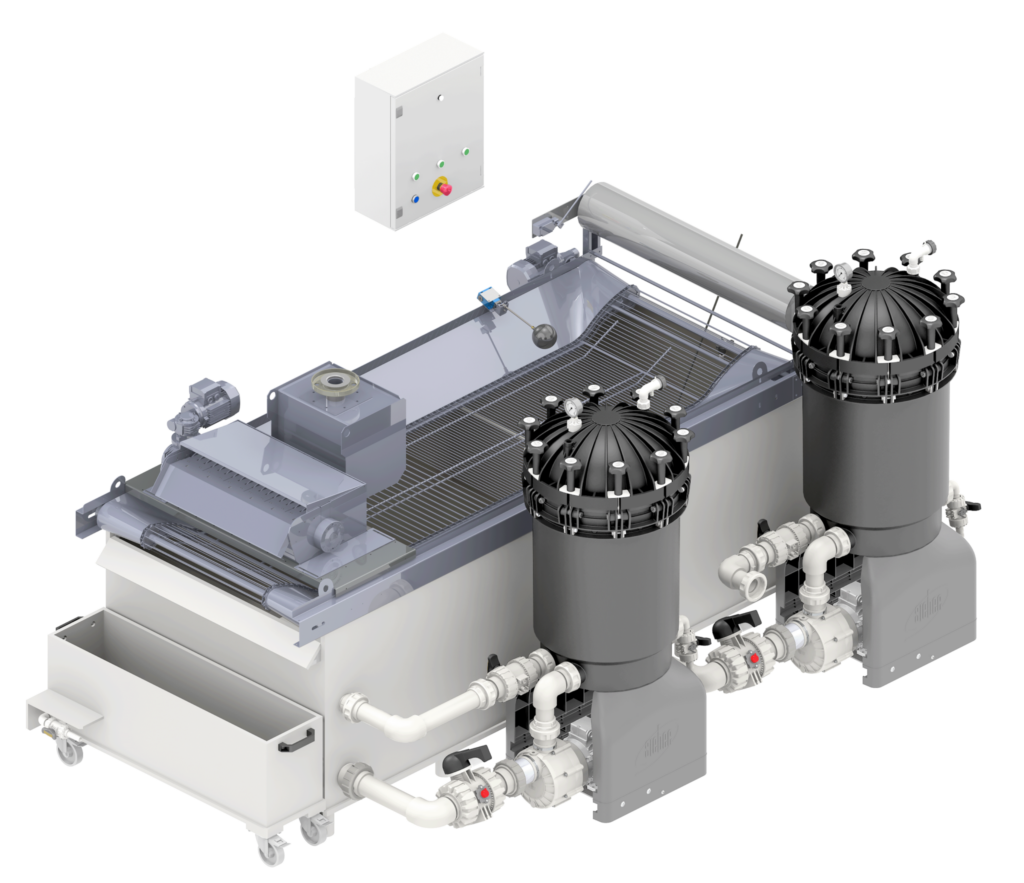

Belt filters for high-pressure cooling lubricants

The CENTRIPURE™ version for metalworking (e.g., grinding, milling, turning) is developed for high-pressure cooling lubricants. The system filters liquids directly into a separate pure tank with an optional volume of up to 2000 liters. It protects machine components, extends tool life and reduces downtime through:

- High-capacity filtration with FILTECH™ cartridges

- Belt filter for sludge and chip separation

- Integration of high-pressure pumps

- Optional heat exchanger (immersion or external)

- Flexible skimmers (floating & surface) for constant oil separation

| Component | Description |

|---|---|

| Pure Tank | 270–2000 l (depending on version) |

| Temperature Control | COOLTECH™ – Cooling or heating as needed |

| High-Pressure Pump Integration | HP machine pumps integrable directly into the system |

| Belt Filter + MAGTECH™ | Pre-separation of chips & magnetic particles |

| Cartridges & Oil Separation | FILTECH™, OILTECH™, BAGTECH™, MAGTECH™ integrated |

| Portable or Stationary | Stationary or mounted on wheels for flexible machine connectivity |

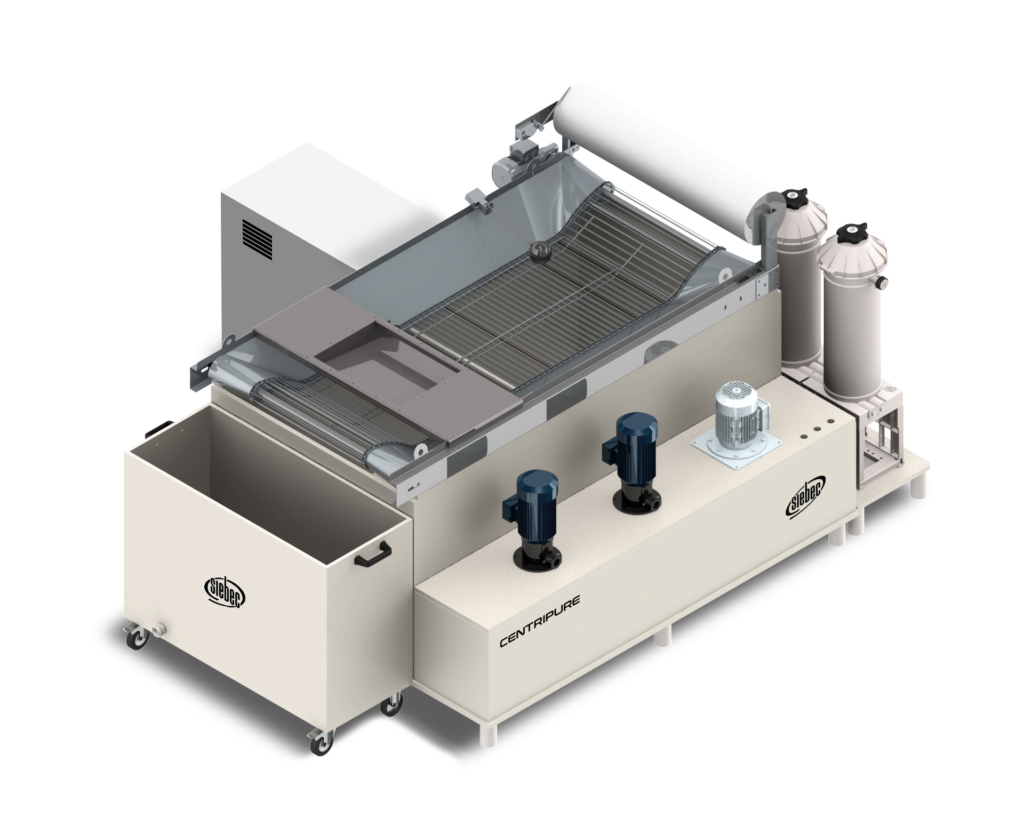

Belt filters for water treatment

The CENTRIPURE™ plant for water treatment processes offers a fully autonomous filtration unit with an integrated belt filter pre-stage. The liquid to be cleaned is filtered directly into a separate pure tank, ensuring a 100% clean return to the process. The system is available as a standard version with a 250-liter tank and two filter housings or as a custom special version with extended components:

- Roll belt filter (BANDTECH™)

- High-pressure pumps

- Tank for sludge and chip separation

- Temperature regulation (COOLTECH™)

- Oil separation (OILTECH™)

- Magnetic filter (MAGTECH™)

- Cartridge filter (FILTECH™)

- Bag filter (BAGTECH™)

| Component | Description |

|---|---|

| Pure Tank | 250 l (Standard) or custom (scalable unlimited) |

| Temperature Regulation | COOLTECH™ – for constant media temperature |

| Belt Filter | BANDTECH™ – automatic media feed |

| Magnetic Filter | MAGTECH™ – 3000–11000 Gauss, 5 kg particle capacity |

| Oil Separation | OILTECH™ – hydrophobic microfiber, 500 g = 6 l oil separation |

| Pre- & Fine Filtration | BAGTECH™ (150–600 µm), FILTECH™ (1–100 µm), tool-free |

Applications of belt filters

- Electroplating & surface technology

- Machining, CNC, high-pressure cutting

- Process water treatment

- Wash & rinse baths

- Cooling lubricant treatment

- Wastewater from metalworking

What distinguishes our belt filter systems

Belt filter systems are a reliable solution for the purification of industrial liquids. Their modular design, tool-free handling and robust construction offer several advantages:

Our services around belt filter systems

Consulting and planning:

We analyze your requirements and develop customized filtration solutions with CENTRIPURE™ belt filter systems.

Installation and commissioning:

Professional setup and fast commissioning ensure a smooth start of your filtration system.

Maintenance and repair:

Regular inspection, quick troubleshooting and spare parts service ensure maximum availability of your belt filter system.

Contact

What are you waiting for? Request a consultation or an offer for our products now.