Submersible centrifugal pump systems for aggressive media

Our submersible centrifugal pump systems are built in a vertical centrifugal pump design and made from PVDF and stainless steel for maximum resistance to aggressive media. They ensure stable conveying performance, corrosion protection and long service life in demanding industrial environments.

Challenges in Conveying Technology

- Corrosion: Acids and alkalis attack the components of the pumps, affecting their efficiency and lifespan.

- Short lifespan: Standard pumps often do not withstand aggressive conditions and fail regularly.

- High operating costs: Inefficient pumps consume unnecessarily high amounts of energy and incur frequent failures, expensive repairs, and production interruptions.

Submersible centrifugal pump solutions by Bohncke

Submersible centrifugal pumps are specially designed for conveying aggressive media such as acids and alkalis. Thanks to their robust construction and customizable vertical centrifugal pump design, they significantly reduce operating costs by minimizing failures and increasing process efficiency.

ST series – energy-efficient vertical centrifugal pump

The ST series is an energy-efficient vertical centrifugal pump with flow rates from 1,500 to 5,000 l/h.

FLOW

FROM 1,500 TO 5,000 L/H

HEAD

UP TO 7 M

Outsider pumps – vertical centrifugal pumps for abrasive media

This is a heavy-duty submersible centrifugal pump alternative for abrasive media.

FLOW

FROM 1,000 TO 22,000 L/H

HEAD

UP TO 16 M

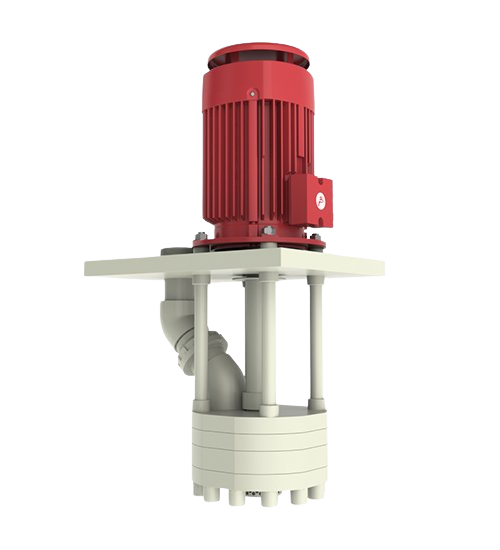

Submersible pumps – high-flow submersible centrifugal pump units

Our submersible pumps operate as fully integrated submersible centrifugal pump units.

FLOW

FROM 1,000 TO 40,000 L/H

HEAD

UP TO 32.5 M

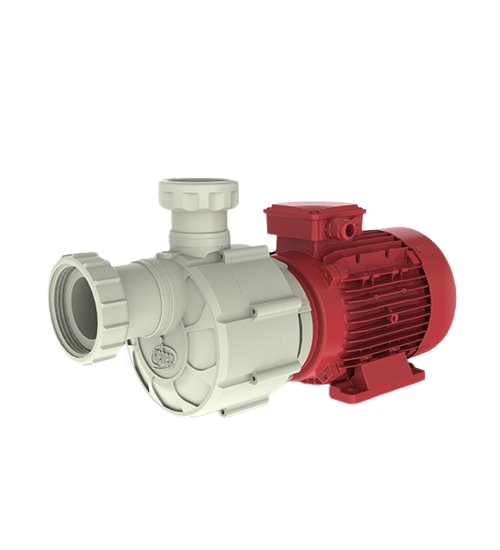

Mechanically sealed centrifugal pump – vertical design for high flow rates

A vertical centrifugal pump design delivering up to 41 m head.

FLOW

FROM 4,800 TO 57,000 L/H

HEAD

UP TO 41 M

Advantages of our submersible centrifugal pumps

Customizability

We offer tailored solutions precisely adapted to your requirements. Our pumps can be tailored to specific flow rates, variable immersion depths, and special material requirements. This flexibility ensures optimal integration into your existing processes.

Material variety

High-quality materials such as PVDF, PP, and stainless steel are available for conveying aggressive or abrasive media. Each material is carefully selected based on the chemical and thermal requirements of your application to ensure maximum resistance and durability.

Durability and Sustainability

Our pumps are designed to achieve a lifespan of ten years, depending on the area of application. The robust construction minimizes maintenance efforts and significantly reduces downtime. This leads to lower operating costs while helping to conserve resources and protect the environment.

Versatile Applications

Our submersible centrifugal pumps or vertical centrifugal pumps are successfully used in numerous industries. In electroplating, they convey electrolyte solutions and aggressive chemicals, while in the chemical industry, they ensure the safe transport of corrosive liquids. In wastewater technology, they reliably handle the processing of wastewater and chemically contaminated media.

Bohncke GmbH: Your partner for submersible centrifugal pumps

What is a submersible centrifugal pump and how does it work?

Submersible centrifugal pumps are designed to reliably handle high flow rates and continuous operation. They are completely submerged in the conveyed medium, allowing for constant and even conveying. The pump uses rotational motion to transport the medium evenly and dependably through a closed system. The centrifugal effect creates a consistent circulation of the liquid. Since the drive is separated from the medium, the pump operates consistently and stably even under demanding conditions.

Contact

What are you waiting for? Request a consultation or quote for our magnetic drive centrifugal pumps now.