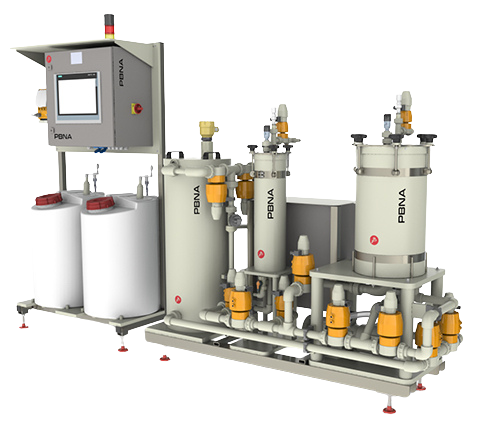

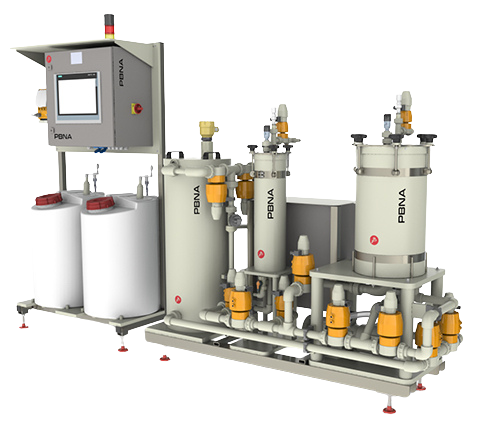

Nickel plating equipment for satin and bright electroless nickel plating

Our satin nickel systems enable stable, reproducible processes for decorative coatings and bright electroless nickel plating. Each PBNA unit automates dosing, cleaning and color management to ensure consistent results with reduced chemical consumption. As specialized nickel plating equipment, the systems minimize waste and support continuous operation.

Minimal waste rate

Reduced chemical consumption

Less maintenance

Overview of our nickel plating equipment options

PBNA 1st gen – entry-level nickel plating equipment for consistent results

The first generation of our Permanent Blend-Free Nickel System is ideal for small to medium applications with consistent requirements.

It offers simple control via a display where the delivery rate is manually set. Dosing is linearly dependent on the output – without complicated settings on frequency converters or valves.

Core functions & attributes:

- Delivery rate adjustable on the display

- Main and maintenance filtration in one unit

- Manual basic setting of the dosing pump (required once)

- Reproducible results through consistent settings

- Up to 2 dosing pumps and containers possible

- No display, no automatic process control

- No password protection or color management

Who is it suitable for?

For businesses looking for a reliable but manually operated system without frequent color changes or high complexity.

PBNA 1st gen – entry-level nickel plating equipment for consistent results

The second generation brings a significant expansion of functionality: An integrated PLC enables automatic dosing, storable colors, and convenient operation via touch panel. Color changes can be implemented at the push of a button – without hardware intervention.

Core functions & attributes (in addition to 1st GEN):

- PLC control with 7″ touch display

- Color management for up to 99 recipes

- Automatic dosing of additives (“Make-up”)

- Monitoring of dosing amounts directly on the screen

- Up to 5 dosing containers & pumps integrable

- Password protection and user log

- Self-priming pump and dry-run protection

- Remote maintenance via TeamViewer possible

Who is it suitable for?

For companies with changing product requirements that need to switch colors quickly while valuing user guidance and process monitoring.

PBNA 2nd gen – automation and color management for nickel processes

The third generation is our flagship for fully automated continuous operation. Additional automatic valves handle rinsing, draining, venting, and pre-coating – with clearly defined control logic for each operating mode. Each work step is traceable, documented, and nearly error-free.

Core functions & attributes (in addition to 2nd GEN):

- Automatically controlled valves for all process modes

- Guided pre-coating with filtering aid and activated carbon

- Automatic draining and cleaning of the filters

- Automatic rinsing of the system and pre-coating containers

- Individual ventilation units integrated

- 15″ touch display with multilingual menu guidance

- Comprehensive data capture: delivery volumes, pressures, valve positions

- Industry 4.0 Ready through complete process integration

Who is it suitable for?

For large electroplating companies with highest demands on automation, traceability, and continuous operation – even across multiple shifts, 24/7.

Structure and functionality of the PBNA systems

The PBNA systems integrate filtration technology, dosing control, and process monitoring in a compact system. They perform tasks such as:

- Filtration of the nickel bath (main and maintenance filtration)

- Dosing of emulsions and additives

- Automated rinsing, venting, and cleaning

- Color change via different supplementary concentrations

- Process monitoring via PLC and data capture

What makes our satin nickel systems special?

Satin nickel coatings andbright electroless nickel plating set the highest demands on process stability, operation, and quality assurance. Conventional systems quickly reach their limits here: Fluctuating surface quality, manual operation errors, high chemical consumption, and unnecessary downtimes are typical problems in continuous operation. This is exactly where our PBNA systems (Permanent Blend-Free Nickel Systems) step in.

Our systems were developed to specifically solve these challenges – enabling a stable nickel bath operation over several days, without quality loss or interruptions. Depending on the upgrade level (1st, 2nd, or 3rd GEN), the systems offer different levels of automation, which always have one thing in common: They relieve the operating personnel from labor-intensive and error-prone tasks – from dosing to rinsing to bath maintenance.

Through precise, quantity-dependent dosing, emulsions and additives are supplied in the correct ratio – reducing chemical consumption and avoiding over- or under-dosing. Production managers benefit from consistent, reproducible coating results and minimized waste rates – especially for demanding decorative surfaces.

Typical challenges – and how PBNA solves them

In galvanic satin nickel processes, similar problems frequently arise – from quality deviations to high personnel requirements to lack of process control.

Fluctuating quality and high waste

Challenge: Unstable bath concentrations and inaccurate dosing lead to uneven surfaces and waste, especially with sensitive workpieces.

PBNA solution: Automated dosing, continuous bath movement, and precise additive control ensure a consistently stable matte finish – reproducible and process-safe.

High personnel effort and slow changeovers

Challenge: Manual cleaning, rinsing, and conversion processes are time-consuming and tie up valuable personnel resources.

PBNA solution: Automated cleaning and rinsing programs and color management with up to 99 colors (from 2nd GEN) enable fast product changes – even in shift operations without electroplating expertise.

Error-prone due to manual operation

Challenge: Manual processes carry a high risk of mishandling and require intensive training.

PBNA Solution: Guided process flows, automatic valve settings (from 2nd and 3rd GEN) and password-protected settings prevent mishandling. The intuitive touch interface allows safe handling – even by untrained personnel.

Lack of transparency and limited system availability

Challenge: Lack of process data, manual ventilation, and unexpected downtime hinder continuous use.

PBNA Solution: Data logging and evaluation of process parameters (from 2nd GEN) as well as automatic ventilation, draining, and cleaning (3rd GEN) provide maximum transparency, traceability, and uninterrupted 24/7 operation.

Benefit advantages for your production

This is what our satin-nickel systems specifically achieve:

Minimal rejection rate

through reproducible results in every batch.

Low chemical consumption

through precise dosing & controlled addition

Error minimization

through automatic processes guiding operators through all steps

Less maintenance

through automatic venting, rinsing, and filter cleaning (3rd GEN)

User-friendliness

through visual operating interface (7"–15" display, depending on model)

Less personnel commitment

through PLC control and guided processes

Quick color changes

with up to 99 storable shades (from 2nd GEN)

Plannable processes

through complete documentation of all operating data

Production security

through stable processes, reduced downtime

Here is where our systems are used

Fields of application for nickel plating equipment

Electroplating operations focused on decorative matt nickel coating and bright electroless nickel plating

Producers for sanitary, household, or automotive components

In-house electroplating facilities with a need for high system availability

Contact

What are you waiting for? Request a consultation or quote for our magnetic centrifugal pumps now.