Nickel recovery: Secure nickel instead of flushing it away

Where nickel losses occur and why you should act

Electrodialysis: The smart solution for your nickel recovery

Functionality

Typical applications of the system

Electrodialysis is ideally suited for:

- Recovering nickel from rinse baths

- Pre-concentrating before thermal processing

- Desalting process fluids for water reuse

In addition to nickel, other metals such as copper, silver, or gold can also be recovered with this process.

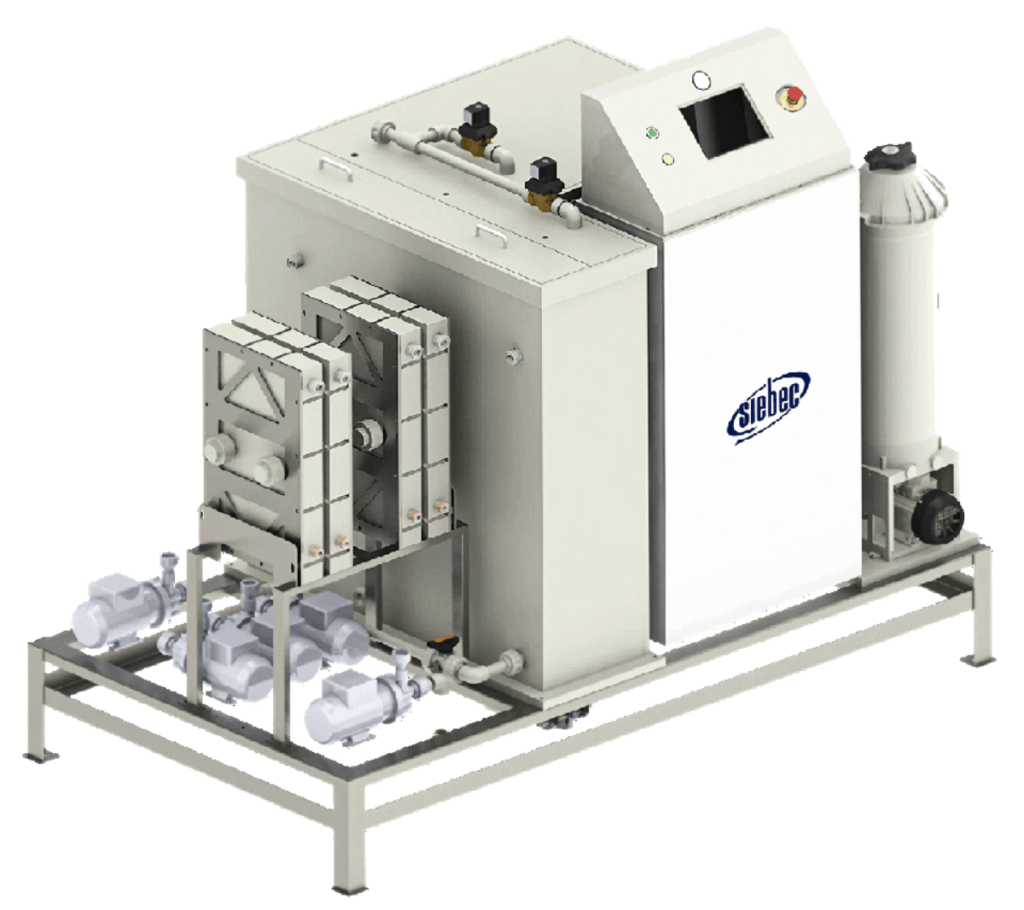

Technical features of the electrodialysis system

Our electrodialysis systems are compactly designed and can be flexibly integrated into existing production processes. The robust construction with chemical-resistant materials such as polypropylene or PVDF ensures a long service life, even under demanding process conditions.

The systems operate energy-efficiently and require no additional chemicals. An automatic control monitors all important process parameters such as voltage, current, and flow rate. This keeps the operation stable, low-maintenance, and economical.

Depending on requirements, we can design the system in different sizes and performance levels. This way, you get exactly the solution that fits your throughput and space conditions.

Advantages of nickel recovery with electrodialysis

Typical areas of application for nickel recovery

Nickel losses affect many industries, but in certain areas, recovery is particularly economical:

- Electroplating operations: Large amounts of nickel-containing rinse water accumulate daily. Recovery reduces material losses and significantly lowers wastewater costs.

- Electronics manufacturing: Nickel coatings on circuit boards or plug contacts lead to nickel residues in process and rinse baths. Recovery stabilizes bath quality and saves raw material costs.

- Metal processing: When processing nickel-coated components, nickel ions are lost with each cleaning step. Recovery reduces raw material consumption and eases wastewater treatment.

- Recycling companies: In processing scrap materials, nickel recovery increases valuable material yield and reduces waste volume.

Contact

Would you like to know how much nickel you are currently losing unnoticed? Or directly request a quote for your nickel recovery?

Then speak with our experts now. We analyze your processes, determine your savings potential, and develop a customized solution for your company.