Filter pumps for electroplating - Bohncke GmbH

Electroplating: When standard is no longer enough

In the electroplating industry, standard pumps are often a weak point because they cannot meet the special requirements such as aggressive chemicals, fine particles, and high temperatures. They often show high wear due to corrosion and material fatigue, leading to premature failure.

Residues like fine particles can cause blockages that impair the operation of the plant. In addition, the delivery performance is often inadequate, resulting in inefficient processes and poorer results. All these factors increase maintenance requirements and lead to higher costs and longer downtimes.

Our filter pumps for electroplating

The most important at a glance:

- For demanding media

- Up to 50m delivery head and 57000l/h flow rate

- Fewer failures and long service life

Our pumps for electroplating at a glance

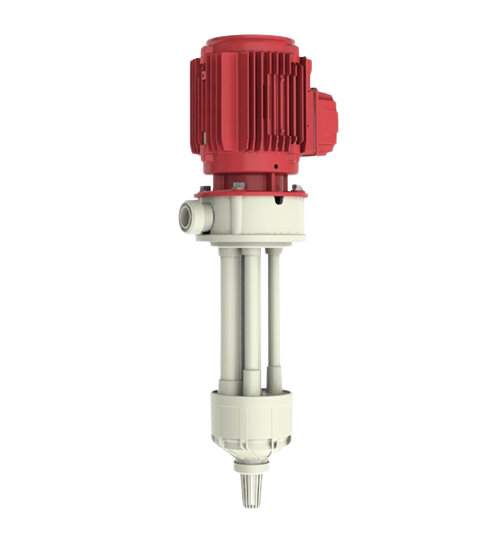

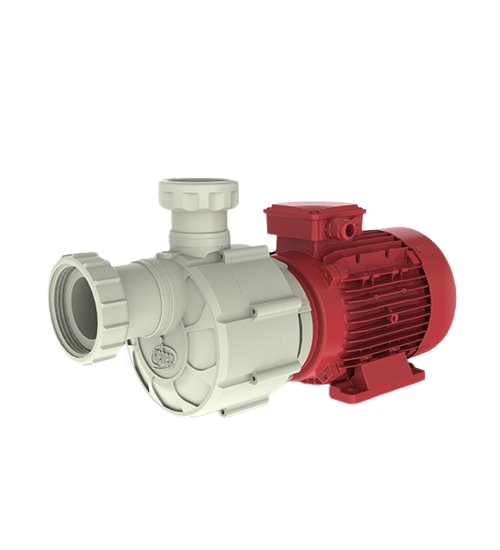

Outsider pumps

Outsider pumps are the ideal solution for applications where liquids with high viscosity or abrasive particles need to be conveyed. Their robust design makes them particularly suitable for conveying sludge process fluids.

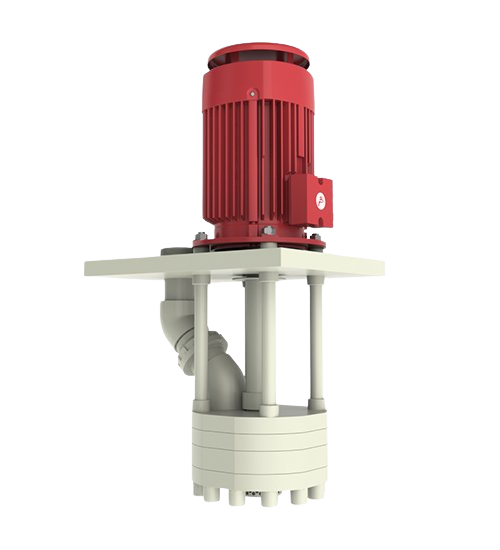

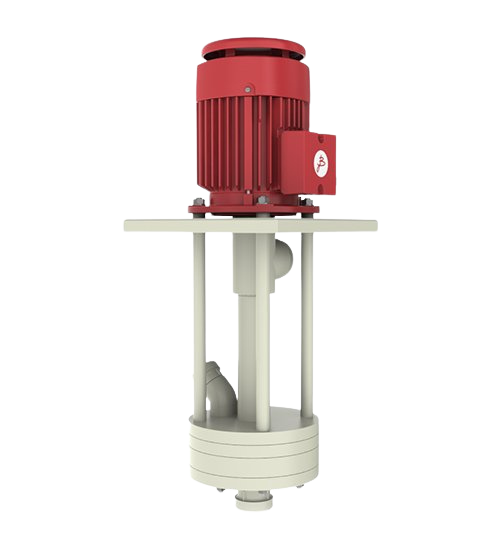

Submersible pumps

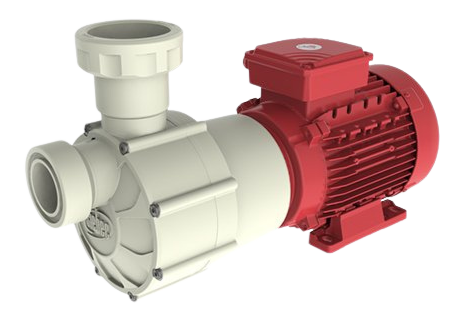

Magnetic centrifugal pumps

Centrifugal pumps

Application areas in electroplating

- Pumping and filling electroplating baths: Safe transfer of acids, alkalis, and process solutions.

- Circulation of baths: Uniform mixing for optimal process conditions.

- Conveying electroplating wastewater: Efficient transfer and safe handling of wastewater with chemical residues.

- Transfer of highly aggressive chemicals: Transport of acids, alkalis, and other corrosive media.

- Coolant supply: Ensuring continuous coolant supply in electroplating processes.

- Filtration and purification of process fluids: Use for removing suspended solids and impurities.

- Conveying high-purity chemicals: Safe use in sensitive processes with no risk of contamination.

- Chemical transfer within the plant: Reliable transport and distribution of process chemicals.

- Dosing of acids, alkalis, and additives: efficient and safe transfer for consistent concentrations.

What makes our filter pumps special

Our filter pumps are specially developed for the requirements of electroplating and offer numerous advantages that set them apart from standard solutions.

Why our customers trust us

Contact

What are you waiting for? Request a consultation or quote for our magnetic centrifugal pumps now.