Electroplating pumps for galvanic and chemical applications

Our electroplating pumps are designed for demanding media in galvanic processes. Unlike standard units, each galvanic chemical pump ensures stable performance, long service life and reliable handling of aggressive liquids and residues. This guarantees smooth operation even under continuous load.

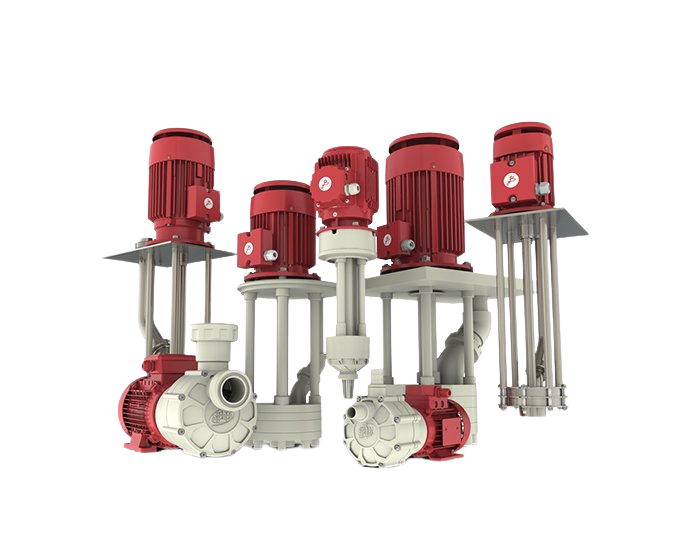

Overview of our Electroplating Pumps

Outsider pumps – galvanic chemical pump for abrasive media

These outsider pumps are ideal for viscous liquids or liquids containing abrasive particles. Their chemical resistance makes them suitable as galvanic chemical pump units for slurries and polluted plating wastewater.

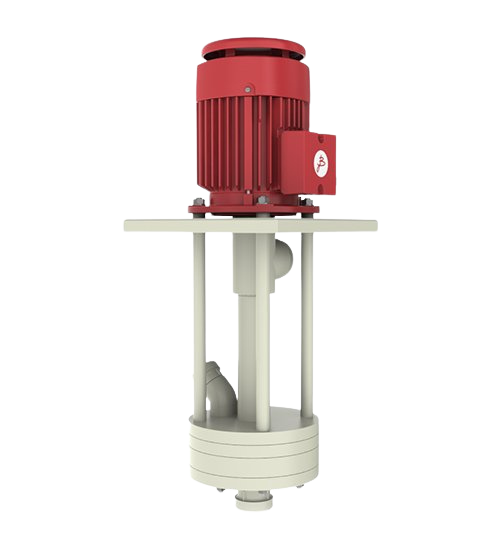

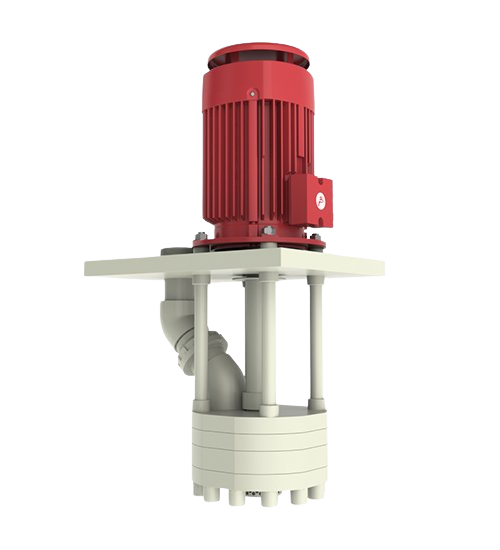

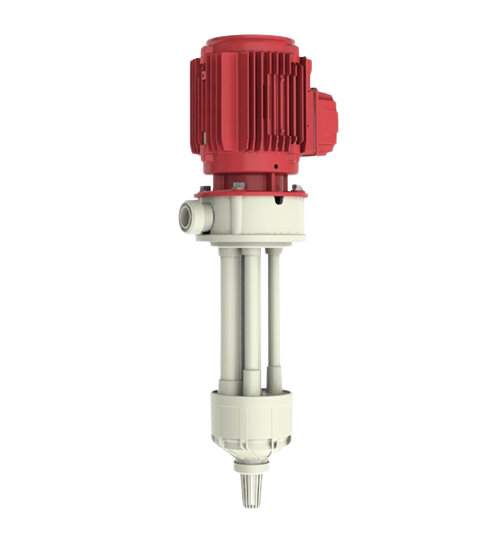

Submersible pumps for direct operation in plating baths

For direct pumping from containers or plating baths, submersible pumps are the optimal choice. They are made of corrosion-resistant materials like PP and PVDF, making them ideal for acids, alkalis, and other aggressive chemicals.

Magnetic centrifugal pumps for ultra-pure chemicals

These pumps operate without contact and prevent leaks through magnetic coupling. They are perfectly suited for the safe transfer of ultra-pure chemicals, offering maximum safety in sensitive processes.

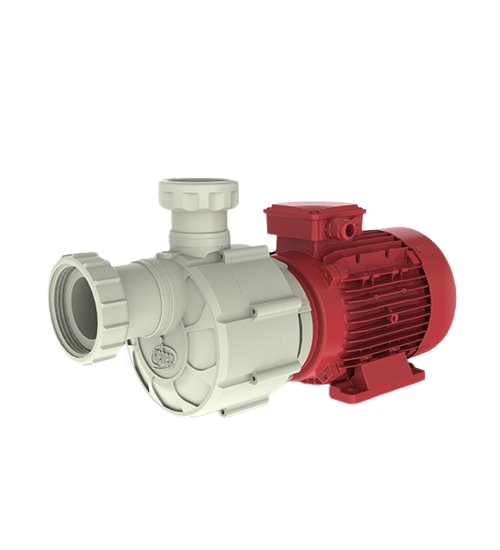

Centrifugal pumps for circulation and chemical transfer

Our centrifugal pumps made of PP/ PVDF offer high flow rates and resistance to concentrated acids and aggressive media. They are primarily used for bath circulation or chemical transfer and are convincing through efficiency and durability.

The Problem with Standard Pumps in Electroplating

Standard pumps often fail due to aggressive chemicals, residues, fine particles, and high temperatures in electroplating environments. They lack the resistance and performance needed for stable plating processes.

- High wear due to aggressive media: The chemicals and residues used in electroplating processes often attack the materials of the pumps. Standard pumps are often not designed for these loads, leading to corrosion and premature failure.

- Clogs due to residues: Fine particles, as they arise during aluminum removal, easily get stuck in standard pumps. This not only leads to clogs but can also impair the operation of the entire system.

- Insufficient pumping performance: Standard pumps are often not tailored to the specific pumping needs of electroplating, leading to inefficient liquid transfer and uneven circulation. This can negatively impact process quality.

- High maintenance effort: The lack of resistance and the frequent failures of standard pumps result in increased maintenance efforts, thus leading to additional costs and downtimes.

Advantages of our Electroplating Pumps

- Robustness: Resistant to aggressive chemicals and harsh conditions.

- Maintenance Friendliness: Easy to maintain, spare parts available even after 10 years.

- Energy Efficiency: Optimized energy consumption for lower operating costs.

- Sustainability: Durable and resource-efficient due to less wear.

- Operational Safety: Maximum process stability and leak protection.

- Customizable: Performance, dimensions, and immersion depth can be flexibly adjusted.

- Durability: Lifetime of at least 10 years, rare replacement cycles.

- Chemical Resistance: Safe handling of acids, alkalis, and aggressive media.

- Flexibility: Versatile for various applications.

Application possibilities for galvanic chemical pumps

Our pumps are suitable for:

- polluted liquids from galvanic processes

- residues from aluminum removal

- plating wastewater

- suction & filling of galvanic baths

- bath circulation

- liquid transfer within plating systems

The Case for BOHNCKE

Specialization and Expertise

As a manufacturer of filter equipment and filter pumps, we know the special challenges in the electroplating and chemical industries exactly and provide the optimal solutions for them.

Individual Adjustments

Our products – from submersible pumps to magnetic centrifugal pumps to nickel platting units – can be individually tailored to performance, dimensions, and operating conditions.

High Quality and Durability

Our pumps and filter units are made of robust materials such as PP, PVDF, and stainless steel, which withstand even aggressive media and guarantee a long lifespan.

Sustainability and Efficiency

We rely on energy-efficient technologies and durable products that reduce operating costs and protect the environment.

Maintenance Friendliness

Our products are easy to maintain and operate. Spare parts are available even after 10 years, saving you time and costs in the long term.

Versatility

From handling aggressive chemicals to bath circulation to filtration – our solutions cover a wide variety of applications.

Maximum Process Safety

BOHNCKE products guarantee reliable and trouble-free operation, stabilizing your operational processes and ensuring the quality of your results.

Why Our Customers Trust Us

Contact

What are you waiting for? Request a consultation or offer for our magnetic centrifugal pumps now.