Chemical pumps: Tailor-made for electroplating and chemical industry

Your challenges - our solutions

As a company in the chemical industry or electroplating, you often face the following challenges:

-

Pumping corrosive liquids: When pumping highly corrosive or aggressive liquids, such as acids or alkalis, you need a reliable solution that withstands extreme conditions.

-

Specific requirements for performance, materials, or design: In some processes, individual adaptation of pump performance, materials used, or design is essential to achieve optimal results.

- Operation under aggressive chemical conditions: In industrial environments where aggressive chemicals are used, you need pumps specifically designed for these challenges.

At BOHNCKE, we understand your challenges and offer you specially tailored solutions. Our experts provide comprehensive advice and support you in finding the right pump for your individual requirements, ensuring your processes run smoothly and reliably.

Advantages of our chemical pumps

Durability

Our chemical pumps are particularly durable and well-suited for demanding industrial applications. Their long lifespan reduces the need for frequent replacement cycles, thereby lowering operating costs. With proper use, our pumps achieve a lifespan of at least ten years.

Individual adaptability

Our pumps can be customized. We offer tailor-made solutions that are precisely matched to the requirements of our customers, whether in performance, dimensions, or materials used. This allows our pumps to be optimally integrated into existing systems and processes.

Material variety and chemical resistance

Thanks to the material variety of our chemical pumps, they offer high chemical resistance and efficiency. We use chemical-resistant materials that provide high safety and ensure that the pumps operate reliably even under extreme conditions.

Variants of our chemical pumps

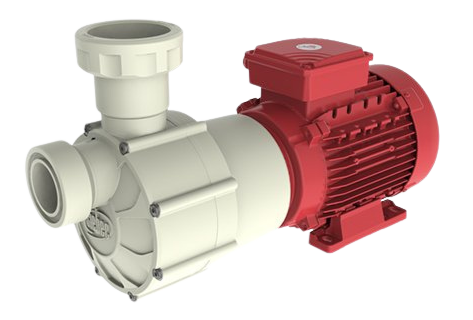

Magnetic centrifugal pumps

Our magnetic centrifugal pumps are particularly suitable for the reliable pumping of aggressive chemical liquids requiring hermetic sealing. These pumps offer high chemical resistance and are ideal for use in electroplating plants and chemical processes.

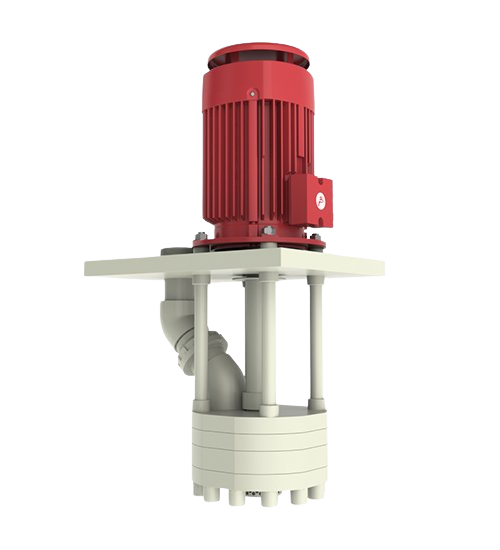

Immersion pumps

Our immersion pumps are designed to be directly immersed in aggressive liquids. They are ideal for applications such as electroplating processes, where the pump must be operated continuously in the medium.

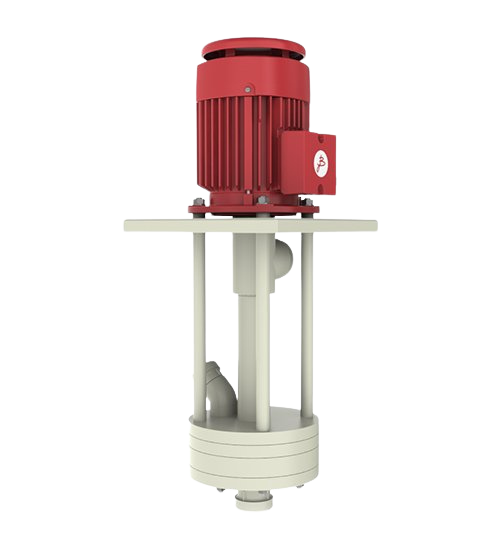

Outsider pumps

For special applications where standard solutions are not sufficient, we offer outsider pumps. These pumps are flexibly configurable and can also be used under special installation conditions, such as in hard-to-reach areas.

These materials we offer

PP (Polypropylene):

Resistant to many aggressive chemicals, ideal for less demanding applications.

PVDF (Polyvinylidene fluoride):

Offers excellent chemical resistance as well as high temperature resistance, ideal for applications with demanding chemical liquids or aggressive substances.

PVC (Polyvinyl chloride):

Cost-effective solution, particularly suitable for standard applications where neither extreme chemical stress nor high temperatures occur.

Stainless steel:

Robust and durable, especially suitable for abrasive liquids and applications with high temperatures.

Typical areas of application for our chemical pumps

Electroplating industry

Companies use our pumps to convey electrolyte solutions and other aggressive chemical substances, for example in coating baths or circulation systems

Chemical industry

In the chemical industry, they are used for transporting corrosive chemicals within production processes, such as acid transport or alkali pumping.

Water and wastewater technology

Our chemical pumps are also used in water and wastewater technology, such as for pumping wastewater or chemically contaminated liquids in treatment plants and industrial wastewater.

Our services

-

Customized manufacturing: All our pumps and filter devices can be individually adapted to your specific requirements.

-

Maintenance and repair service: We offer comprehensive maintenance and repair services to extend the life of your equipment and ensure its efficiency.

-

Spare parts and installation: Spare parts are available even after more than ten years, and our technicians assist you with installation.

- Consultation and planning: Our experts are happy to provide personal advice and assist you in planning and selecting the appropriate products for your application.

Why choose BOHNCKE GmbH?

Why our customers trust us

Contact

What are you waiting for? Request a consultation or offer for our chemical pumps now.