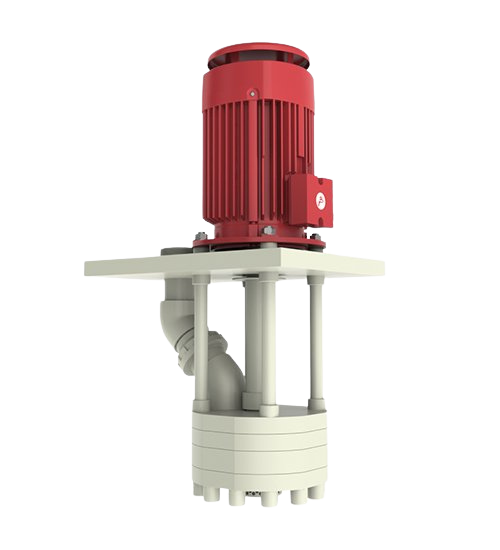

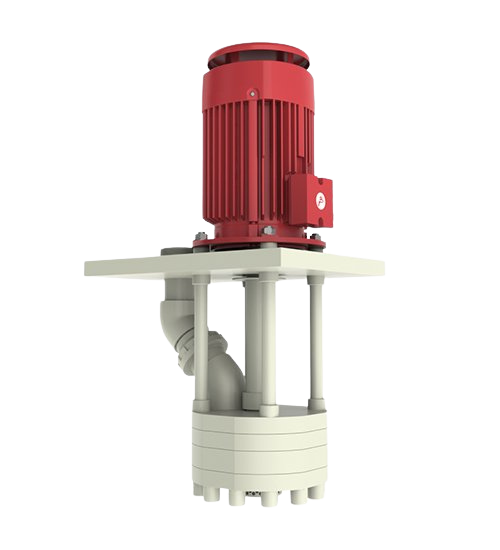

Submersible pumps for industry – efficient conveyance

Submersible pumps: When standard is no longer enough

Companies in the chemical industry and electroplating often face challenges as standard pumps do not meet specific requirements. These pumps are often not robust enough to withstand aggressive media, do not offer the required performance, or have the wrong dimensions. This leads to increased maintenance requirements, breakdowns, and production disruptions.

Therefore, companies in such cases need special submersible pumps to ensure efficient operations without unnecessary interruptions. Our submersible pumps offer the ideal solution for such demanding industrial applications.

Our submersible pumps for industry

- Massive material with PVDF-coated stainless steel struts

- Suitable for immersion depths of 200 to 500 mm

- Flow from 1,000 to 40,000 liters per hour

- Robust gray cast iron motor with solid coating

- Delivery heights up to 32.5 meters

Submersible pumps from BOHNCKE: What sets them apart

How submersible pumps work

Vertical pumps are specifically designed for extracting liquids from deep or inaccessible areas. They consist of a motor mounted outside the liquid and a vertical shaft driving the impeller in the medium. This construction enables reliable pumping even at high delivery heights and challenging conditions.

The medium is sucked in by the impeller and transported upwards along the vertical axis. Thanks to the motor’s positioning, it remains dry and protected from contact with aggressive or corrosive liquids, which increases the pump’s lifespan and maintenance-friendliness. Vertical pumps are therefore particularly suitable for applications requiring high reliability and performance, such as in sewage plants, the chemical industry, and mining.

Areas of use for our industrial submersible pumps

Conveyance of chemicals and aggressive media

Cooling water disposal in industrial processes

Wastewater and sludge disposal

Submersible pumps transport wastewater and sludge in sewage plants and industrial wastewater systems. They ensure reliable disposal even with high solid content.

Water disposal and treatment

Why BOHNCKE GmbH?

Why our customers trust us

Contact

What are you waiting for? Request a consultation or quote for our magnetic drive pumps now.

Frequently Asked Questions about our product

Submersible pumps are special pumps that are immersed directly in liquids to convey them. They work within the medium to transport liquids reliably and efficiently. Unlike surface pumps, which are installed outside the conveying medium, submersible pumps are designed for underwater operation.

Choosing the right submersible pump depends on several factors that must be tailored to the specific requirements of your application:

- Flow rate and head: Determine how much liquid is to be pumped per hour and what head is required. These factors directly influence the performance of the pump.

- Type of conveying medium: Check the properties of the liquid to be conveyed, such as viscosity, temperature, and chemical composition. Pay attention to the chemical resistance of the pump, especially when aggressive media are involved.

- Material resistance: Pay attention to the right material. Our submersible pumps are made of chemically resistant materials like PP, PVDF, or stainless steel, making them ideal for aggressive media.