Recovery of precious metals: Targeted retrieval of gold, nickel, and palladium

Gold, nickel, and palladium are expensive and often difficult to replace in production. At the same time, valuable amounts are lost daily through rinse water, process liquids, or fine dust. Taking early action not only reduces raw material costs but also decreases disposal efforts and improves environmental performance. With the right recovery systems, the material cycle can be significantly optimized in many areas.

Securing valuable resources instead of losing them

Every day, valuable resources flow unnoticed out of production. Gold, nickel, or palladium hide in rinse waters, settle as dust, or remain in filter residues. What seems like an unavoidable material loss in everyday operations is, in fact, a tangible resource. With the right recovery technology, you can reclaim these amounts before they are lost for good. This not only secures your raw material supply but also improves the profitability of your production.

Identify and systematically avoid gold losses

Whether polishing, grinding, or electroplating. Everywhere gold is processed, invisible losses occur. Dust disperses on machines and floors. Rinse water contains dissolved gold particles. Filter residues often harbor untapped potential. Extraction systems with finely tuned filter technology and methods for recovery from liquids help to systematically exploit these sources. This way, you avoid costly purchases of gold and increase material yield.

Nickel recovery: Recover raw materials from rinse water

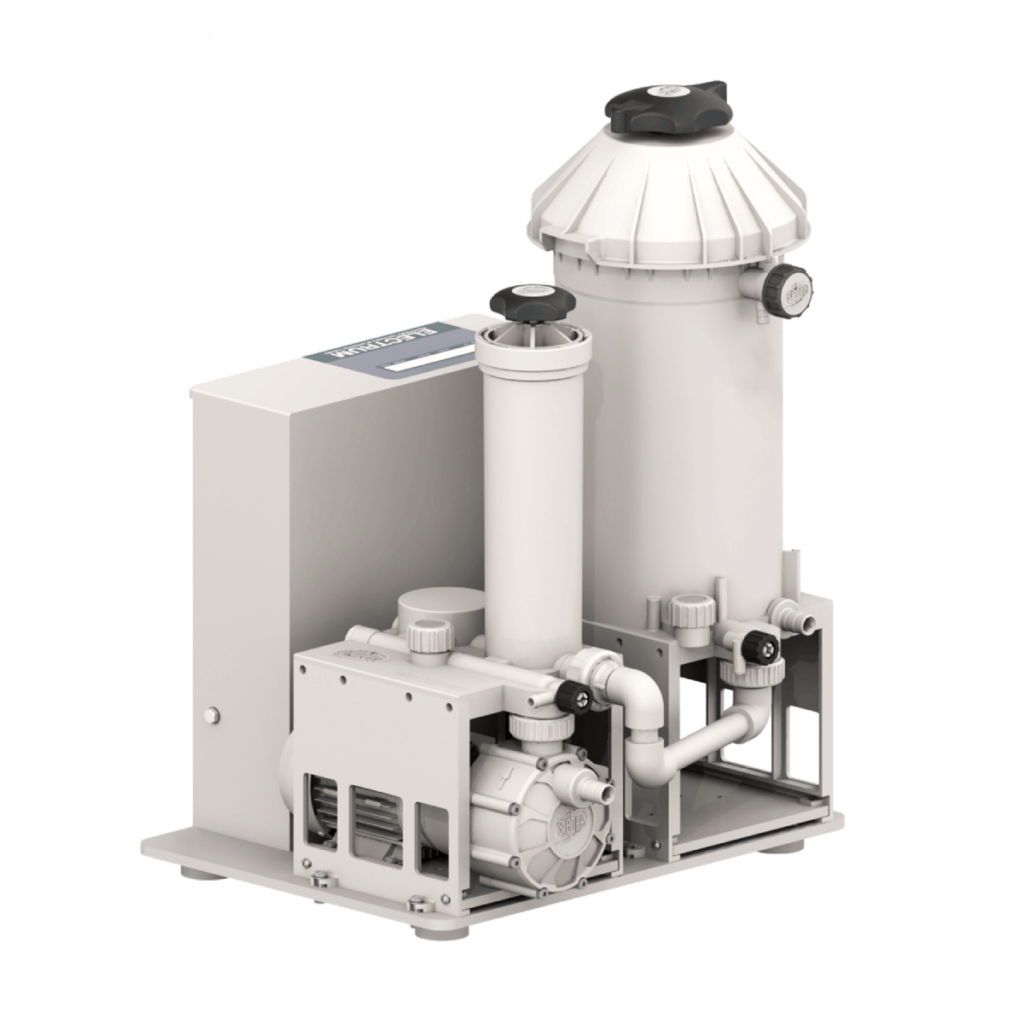

Nickel losses affect many companies in electroplating and metal processing. Especially rinse baths transport nickel ions directly into the drain day by day. Electrodialysis offers an economical solution. It specifically separates nickel from process water and collects it in a concentrated form. This saves raw material costs and reduces the burden on wastewater treatment while maintaining stable water quality for the process.

Palladium recovery: Sensibly utilizing precious metal residues

Palladium is one of the most expensive precious metals. Every loss is noticeably reflected in the balance sheet. Whether in electroplating baths, rinse waters, or filter residues. With electrolytic recovery, you can reclaim these amounts. The process works compact, efficient, and reliable. Even at low concentrations, palladium can be economically separated and reused.

Our service: From analysis to successful recovery

This is how a precious metal recovery project works

Every company has different processes, systems, and challenges. That’s why nothing runs according to a set formula with us. Instead, we develop your solution step by step together with you:

-

Identify losses

The first step is to find out where gold, nickel, or palladium are being lost in your production. We talk to your team, analyze process points, and take samples if desired. -

Assess precious metal potential

Based on laboratory analyses, we show you how much valuable material is present in your process waters, filter residues, or dusts. -

Develop a technical solution

We create a suitable concept. We take into account not only the technology but also your space requirements, existing processes, and budget. -

Examine economic efficiency

You receive a transparent assessment of costs, savings potential, and payback period from us. -

Individual adjustment

Whether a small retrofit or a complete new installation: We plan everything so that it fits into your processes and integrates seamlessly.

Contact

Would you like to learn more about how much palladium you’re currently losing unnoticed? Or do you directly wish to get an individual offer for electrolytic palladium recovery?

Then contact us now. Our experts will personally advise you, analyze your situation, and develop a tailored solution for your operation.

FAQ: Frequently asked questions about precious metal recovery

Is precious metal recovery worthwhile even for small loss quantities?

Yes, and more often than many companies think. Particularly for expensive metals like gold or palladium, recovery often pays off even at very low levels. Even the smallest losses add up to considerable amounts over weeks and months. Additionally, raw material prices are continuously rising. Moreover, there are technical solutions specifically designed for economical operation at low concentrations. Before investing, we thoroughly examine whether recovery is worthwhile in your case.

Can the technology be integrated into our existing plant?

Usually yes. A major advantage of our solutions is their flexible design. Whether it’s an electroplating line, production line, or laboratory operation – we plan the integration so that your existing processes can continue with minimal disruption. Depending on the type of plant, compact designs are also available that require little space. During the planning phase, we coordinate all technical details closely with your building services or plant engineering.

How does recovery affect our production quality?

On the contrary to possible concerns, precious metal recovery often improves process stability. By specifically returning material or cleaning process waters, essential parameters such as precious metal concentrations in the baths remain stable. This reduces variations in coating quality, decreases scrap, and ensures consistently good results. Moreover, maintenance effort in your facilities decreases because fewer solid residues remain in the systems.